- Who We Are

Who We Are

Tweet/Garot has been a family-owned mechanical contracting business for over 120 years. Beyond simply designing and building high-quality mechanical solutions, our industry-best workforce provides a complete commitment to each project and extraordinary customer service.

- Mechanical Construction

Construction

Tweet/Garot design teams continue to push limits of technology within the construction industry. We have created the ability to provide a more detailed mechanical concept model to our construction partners with less information, and in record times.

- Manufacturing

Manufacturing

With nearly 155,000 square feet of prefabrication space, our customers are confident in our ability to not only reduce our man-hours on site and reduce transportation costs, but also help shorten the time required to complete our critical, preliminary work.

- Building Services

Building Services

Tweet/Garot is dedicated to providing our clients with a smarter, energy-efficient, and more comfortable facility, always functioning at peak performance.

- Markets Served

Markets Served

Tweet/Garot specializes in—and is recognized for—our ability to work around our customers’ demanding schedules, no matter what market. We utilize fast-track construction methodology, virtual design technology, and continuous improvement in all that we do. Our clients know that Tweet/Garot thrives on solving challenges.

- Projects

STAAT MODs

Project Information

- Market

- Location

- Maryland

- Owner

- State of Maryland

- General Contractor

- Boldt

- Architect

- HGA

- Engineer

- HGA

- Square Footage

- Approximate Contract

- $565,000

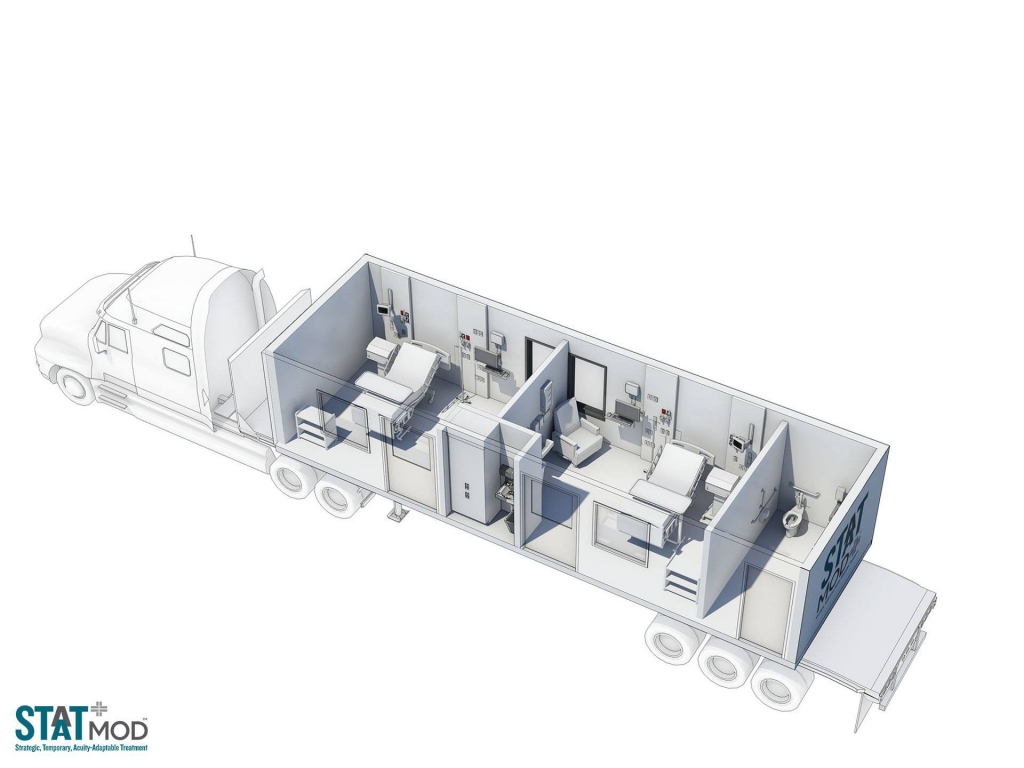

STAAT MODs

Lean thinking in time of crisis. In a response to the COVID-19 pandemic, Tweet/Garot Mechanical, Inc. (De Pere, WI), along with the team of HGA, Boldt and Faith Technologies, collaborated to design an acute care solution in under two weeks. The team set out to achieve three major project goals: provide hospital level clinical care via a modular, prefabricated rapid response solution. At Boldt’s facility in Appleton, the manufacturing team utilized pull-plan sessions to streamline the production process. From start to finish, a module can be completed in less than 10 days. Modular components were designed to maximize transportation constraints using the “C-Can” mindset. As a result, the modular solution allows for true expandability with little design modifications needed to scale bed capacity. Tweet/Garot provided HVAC, plumbing and medical gas services for this project.

With most team members working remote, the project kicked off with a “virtual” big room where component teams worked through design constraints and constructability challenges while considering an “off the shelf” approach – such as a standard HVAC rooftop unit retrofitted to meet isolation room requirements. Utilizing a one-model approach, component teams were able to start clash detection while the design continued to evolve.